Never has it been more important to get more product on a truck – to make every shipment count. Global supply chains continue to face historic challenges, and truck freight is no exception. “We’re literally living in a shipping Armageddon,” Ron, Head of Uber Freight, recently said. Clogged container ports as well as shortages of labor and equipment, combined with supply disruptions and increased product demand, have coalesced to create the current dilemma.

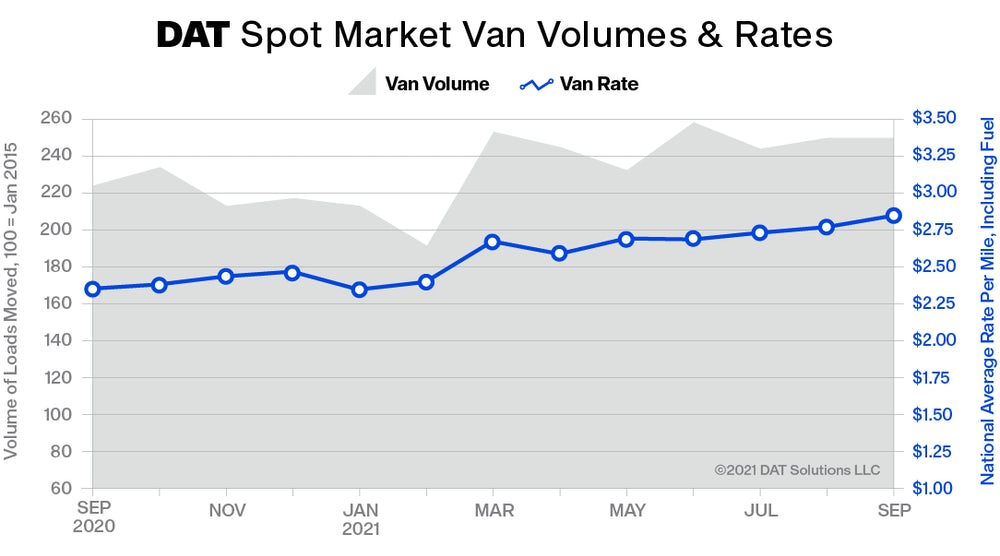

Surging consumer demand has driven unprecedented freight traffic volumes. The DAT Truckload Volume Index (TVI), an aggregated measure of dry and reefer vans as well as flatbeds moved by carriers each month, rose to 231 in August 2021, up 2% from July and 17% higher year over year. It dropped 1% in September, but still the highest for any September on record. Typically, volume declines 7-10% between August and September.

Meanwhile, moving that increased volume has been hampered by driver and equipment shortages. While a driver shortage has been a nagging concern for many years, a recent wave of retirements and people leaving the profession for other reasons has amplified the trend. The closure of driving schools earlier in the pandemic has also resulted in a reduced number of new drivers entering the industry, at least in the short term.

According to a report released in October 2021 by the American Trucking Association, the current shortage of drivers in the United States has risen to 80,000, an all-time high for the industry. “Since we last released an estimate of the shortage, there has been tremendous pressure on the driver pool,” said Chief Economist Bob Costello. “Increased demand for freight, pandemic-related challenges from early retirements, closed driving schools and DMVs, and other pressures are really pushing up demand for drivers and subsequently the shortage.”

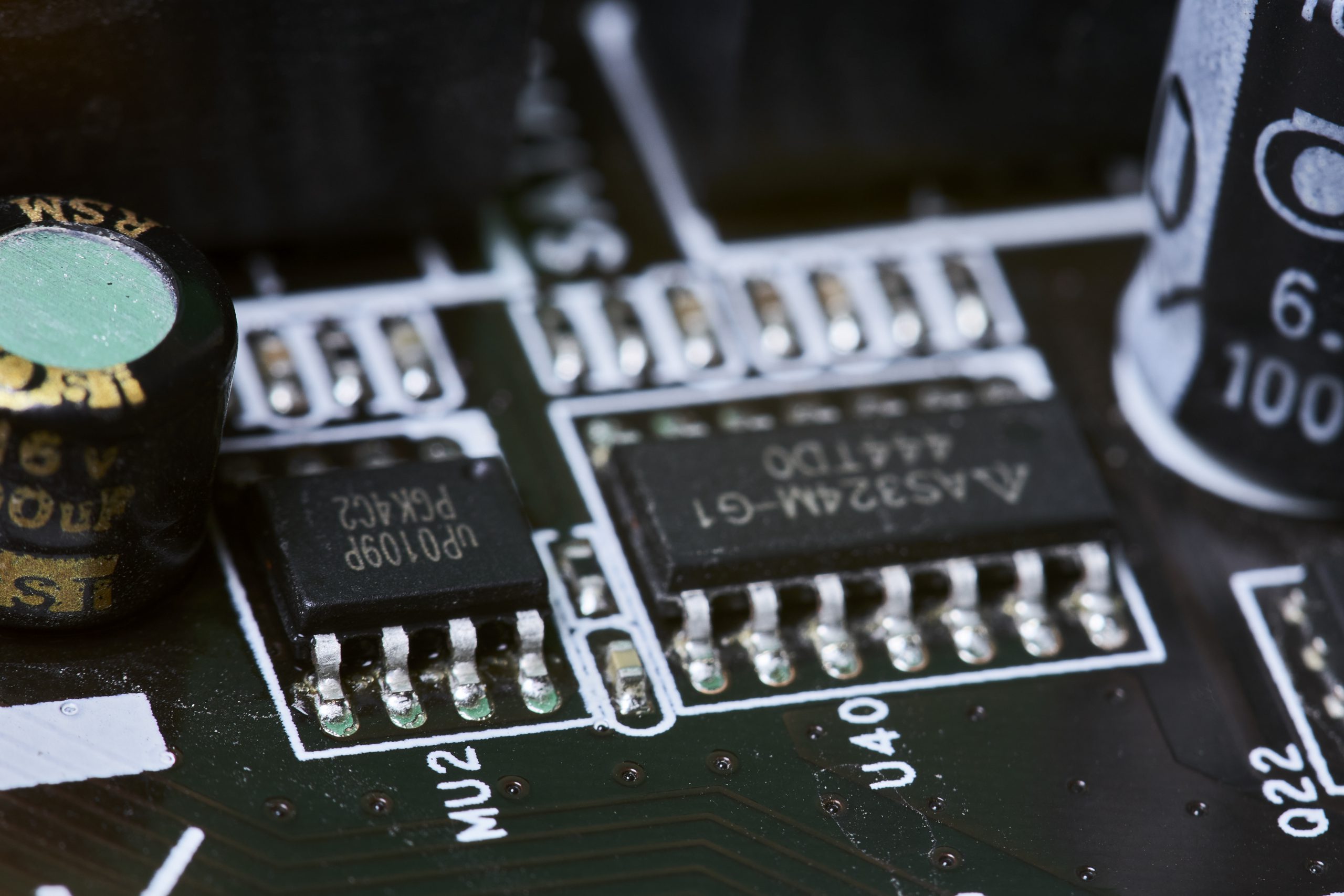

At the same time, truck and chassis availability has also hampered freight operations. The chip and part shortages that have resulted in passenger vehicle supply problems have also impeded commercial truck production in a big way. The semiconductor supply issue is much greater for large tractor-trailers which require many more chips than passenger cars. While tractor-trailer manufacturers would typically produce about 350,000 trailers annually, that amount was cut by about one-half in the last year. Older used trailers that previously would have been sold for scrap are fetching $5,000-$10,000 on the used market.

Meanwhile, the price of container chassis has doubled, and availability is tenuous. While chassis drivers previously might have made seven trips per day, now they might be expected to make as few as three trips, or even just one, due to port congestion. Bottom line, even with the passage of a new infrastructure bill, and various moves to ease port congestion, freight availability can be expected to be in tight supply and expensive for the foreseeable future.

How can shippers get the most out of each load?

One of the few viable ways for shippers to mitigate some of the pain is to ship more product per trailer. Increasingly, cargo optimization software is being utilized to help shippers unearth new opportunities to redesign products, packaging, and unit loads to increase product density.

Another way to optimize loads is to take a fresh look at pallets and go for an option that takes up less space and weighs less. RM2’s BLOCKpal pallet weighs just 55 lbs versus an average of 70 lbs for other block pallets, freeing up capacity for an extra 420 lbs of merchandise. And it isn’t just about weight. With a height of only 5.0” versus 5.67” for other block pallets, there is more room for goods and greater efficiency for pallet backhauls. With BLOCKpal, you get 90 more pallets on each full truckload return.

Not only that, the extremely durable and high-performance BLOCKpal pallets are more efficient to handle, ensuring fewer issues at the dock and in storage systems. If the current freight market is weighing you down and taking too much of your space during the course of the day, you are not alone, and the challenge isn’t expected to go away any time soon. One way to ease the pressure is to reduce pallet height and weight – to make every load count.

To learn more about how BLOCKPal can help optimize your loads, contact us.